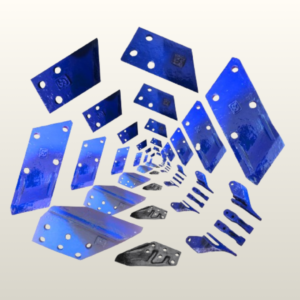

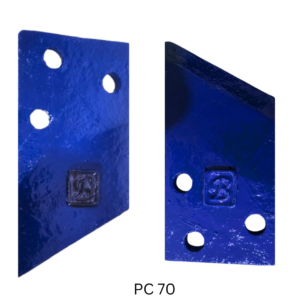

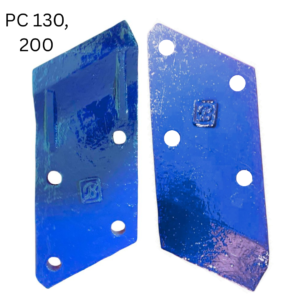

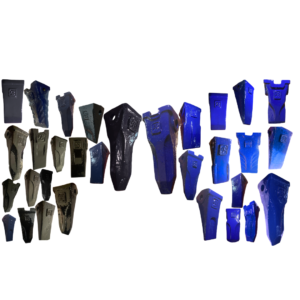

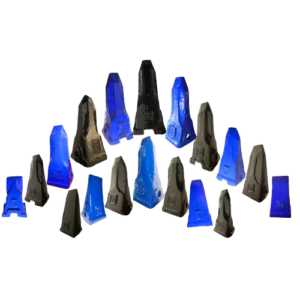

Ball Mill Liner Designs

We offer a comprehensive range of liner profiles to suit different grinding requirements:

-

Wave Liners – Wave type ball mill liners and wave shell liners designed to improve material lifting and grinding efficiency

-

Step Liners – Step liner plates with stepped profiles for controlled grinding media movement

-

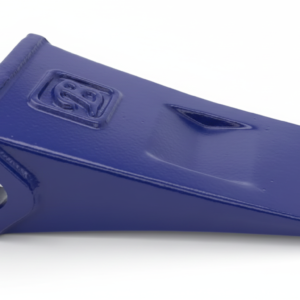

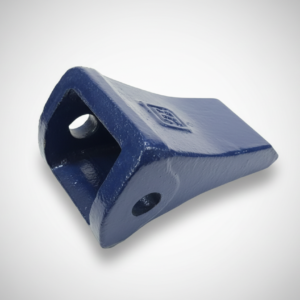

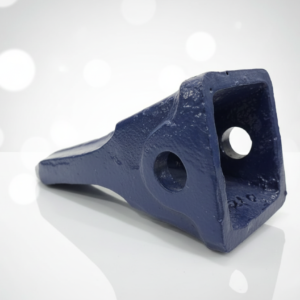

Wedge Bar Liners – Wedge-type liner plates providing enhanced wear life and improved impact resistance

-

Studded Liners – Studded grinding liner plates with anti-slip features for superior performance in heavy-duty applications

These high-efficiency mill liners are engineered to improve throughput, reduce energy consumption, and maximize liner lifespan.

Applications Across Industries

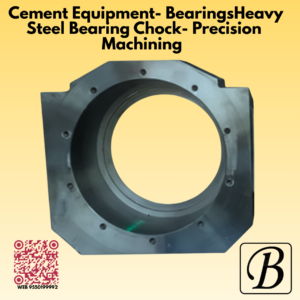

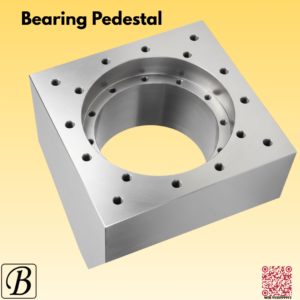

Cement Industry

-

Cement ball mill liners

-

Cement grinding liners

-

Cement mill wear parts

Mining & Beneficiation

-

Beneficiation ball mill liners

-

Ore grinding mill liners

-

Mining mill liner wear parts

Coal Mills

-

Air swept coal mill liners

-

Coal grinding mill liners

-

Coal mill wear-resistant liners

Wet & Dry Grinding

-

Wet ball mill liners with corrosion-resistant properties

-

Dry ball mill liners with heat-resistant performance

Why Choose Our Ball Mill Liner Solutions?

-

High wear-resistance ball mill lining solutions

-

Custom-manufactured mill liners for cement and mining industries

-

Optimized liner designs for improved mill performance

-

Durable grinding mill liners for heavy-duty applications

-

Reliable supplier of ball mill liners and lifter bars

Our custom mill liner solutions are developed to meet specific operating conditions, ensuring the right material, liner form, and performance characteristics for every application. https://businessbharath.com/product/ball-mill-liners/

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.